Aluminum raised floors can be used in the following fields: microelectronics industry (wafer plant, TFT/LCD, packaging and testing, printed circuit boards), semiconductor industry, flat panel display industry, optoelectronics, life science industry, precision engineering and ultra-clean environmental electronics industry.

Characteristics

- Patent design with high dimensional accuracy

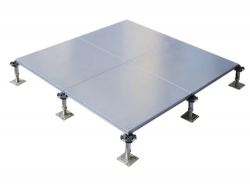

- Light weight and excellent loading capacity

- Conductive and static dissipative coverings and coatings

- Contains no ferrous materials to disrupt magnetic fields

- Excellent rolling load performance

- Die cast aluminum panels meet call A1 fire rating

- Good performance of waterproof

- Pollution and radiation free

- Recyclable and economic system

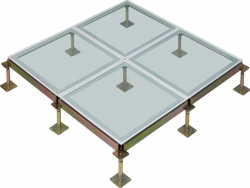

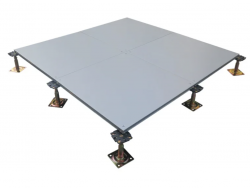

- Various pedestals and structure system

Edge Trim

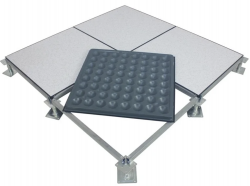

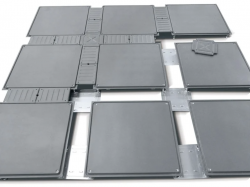

Four edges of panels can be grooved by milling machine, insert PVC edge trim to protect the floor coverings. Refer to below image, left one is trimless type, right one is PVC edge trim type.

Corner Connection

In places with high stability requirements, panels can be connected to the understructures with corner lock holes. Refer to below image, left one is free standing system type, right one is corner lock system type.

Technical parameters

The raised floor will be with a safety factor of three times the concentrated (design) load, and is capable of meeting static and dynamic loads per CISCA Platform (Raised Access) Floors Performance Specification.

Production process

Quality control

Why aluminum solid panel?

Aluminum raised floors’ main applications are clean room, electronic workshops, etc. These environments have lots of Integrated circuits (ICs), which are used on a large scale in integrated circuits. They are more difficult to withstand higher voltages than discrete components. In particular, field-effect transistors must be avoided. Static electricity comes into contact because static electricity can range from tens of volts to more than a few hundred volts and even reach thousands of volts, easily breaking down integrated circuits. Therefore, the electronic dust-free workshop should pay special attention to the generation of static electricity, and it is best to fundamentally eliminate the generation of static electricity.

Compared with other raised floor types, aluminum raised floor has a lightweight and very high load capacity. After installation, it is very stable and will not slide or become wavy due to heavy objects’ passing. Simultaneously, the aluminum raised floor is corrosion-resistant, and there is no treatment on the floor surface, no dust will generate